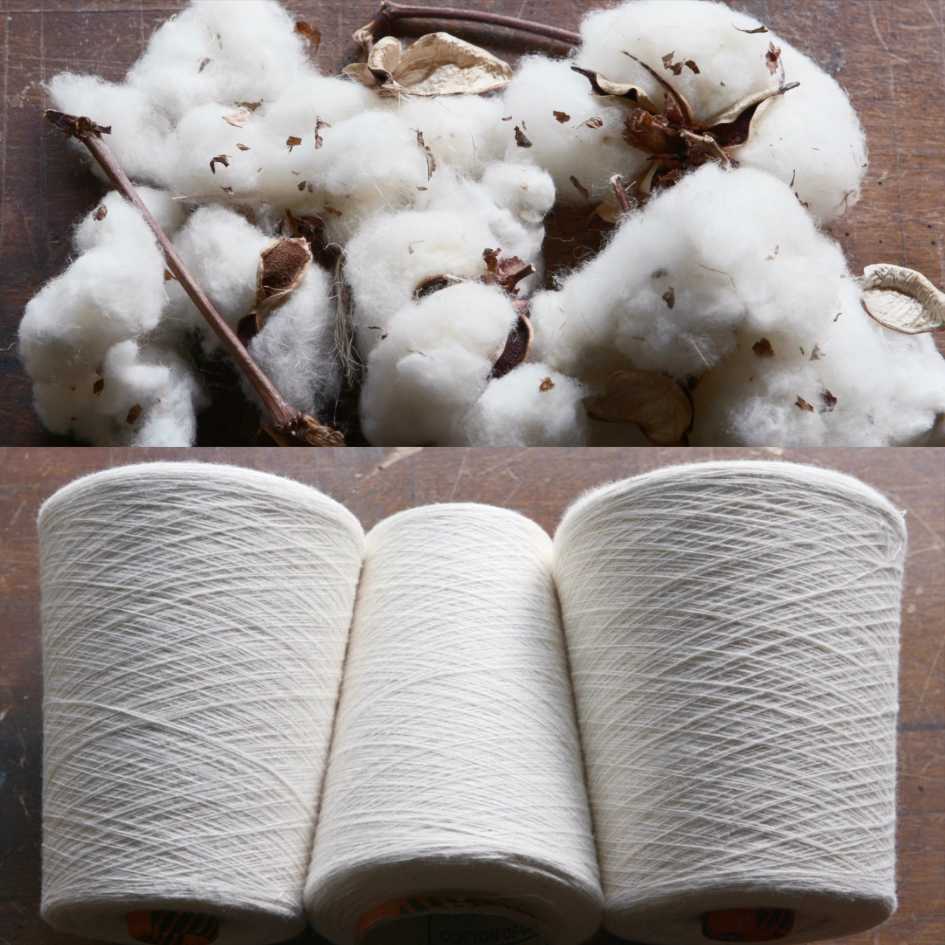

Natural Fibers

Solid State Clothing creates clothes with the planet in mind by using 100% natural fibers, down to the thread. This means our shirts are vegan-friendly and biodegradable. That’s right, our shirts can be put back into the ground!

We have also begun doing some small run accessories with wool and hemp. We aim to only source domestic and ethically produced wool and are committed to using 100% RWS or Nativa certified wool.

Synthetic fibers, such as polyester, nylon and acrylic, are made from fossil fuels. Polyester clothing and textiles are also one of the leading sources of microplastics, tiny plastic particles that have permeated our air, oceans, food, and bodies.

Transparent, Trackable Supply Chain

All of our shirts have a QR code inside the neck or on the hem. Scan it with your phone and you'll see exactly where every step of our USA manufacturing takes place—name, location, website, even a phone number. We have first hand relationships with all of our suppliers, this ensures fair labor practices, which we are committed to.

Tracking the supply chain of clothing gives consumers a deep understanding of where their clothing comes from. This allows them to make educated decisions about where to buy their clothing based on their beliefs.

Textile Recycling

We believe in making clothing, not wasting it. An estimated 92 million tons of textile waste is created annually, and it's either landfilled or burned.

At Solid State Clothing, we're serious about fighting this enormous problem. Our suppliers collect and ship us 100% of the fabric scraps left after our t-shirts are cut and sewn. Some scraps are used in our dye process, but ultimately all unsellable scraps and t-shirts that enter our facility are recycled at Material Return, a textile recycling facility in Morganton, NC. Contact us to have your Solid State Clothing T-Shirts recycled at Material Return.

Reducing Carbon Emissions Through Our Local Supply Chain

Over 97% of clothing sold in the United States is made overseas. An average t-shirt travels 13,000 to 40,000 miles to reach to the end consumer. Upwards of 90% of clothing is on a ship at some point during its manufacturing process.

Our NC supply chain—from ginning to spinning to knitting—covers just 768 miles. That means our supply chain is 96% less than average.

Natural Dyes

We use natural dyes made from responsibly-sourced plants such as pomegranate, madder root, fustic, and black walnut. We’re working to source dye plants from local farmers and have an experimental dye garden on the land around our offices. We do not allow the use of AZO dyes or PFCs in our supply chain. All dyes are low impact and non toxic!

By collaborating with TS Designs—one of the only companies in North America dyeing apparel with natural dyes at scale—as well as local universities and industry experts, we’re developing new colors and processes that are even more beneficial to the environment.

Restoring Local Biodiversity

Our building sits on 4.5 acres, and we’re restoring the land by converting a monoculture of lawn grass to a native plant habitat and garden for food and natural dyes. We’re planting hundreds of native plants, including native food-producing species such as muscadine and pawpaw. A dye garden allows us to experiment with sustainably growing natural color.

These efforts create a healthy, biodiverse landscape that draws down carbon, creates habitat for animals and insects, moderates temperatures around our building, and creates a beautiful workplace for our employees.

Packaging

Packaging accounts for 37% of total plastic waste in the United States. All Solid State Clothing packaging FSC certified, 100% recycled cardboard, 95% of which comes from post-consumer waste, by EcoEnclose. We print the boxes in house with waste-based inks. Order with peace of mind, you will never have to go through layers of plastic to get to your garment!

Community Impact

We are a locally-owned small business, and we’re dedicated to building stronger, more resilient communities in our region.

Our community impact partners include Sustainable Alamance, a local organization that helps individuals who were formerly incarcerated gain and sustain employment; Carolina Textile District, a member-governed and member-driven network of values-aligned textile manufacturers in North and South Carolina; Campus Alamance, a paid internship program at Elon University that allows students to work at local businesses to gain real world experience, and Croatan Institute, an independent, nonprofit research and action institute dedicated to building social equity and ecological resilience by leveraging finance to create pathways to a just economy. In addition, we prioritize partnering with local artisans such as our collaborations with Haand and Tara Reed.